APR MQB 1.8T / 2.0T Carbon Fiber Intake System

The APR Carbon Fiber Intake System is an attractive high performance upgrade for the latest 1.8T and 2.0T engines as found in various MQB platform vehicles. The factory intake design has the foundation for excellent performance, but much of this is sacrificed in an effort to meet other design requirements. With requirements set forth for only supporting factory power output levels, low engine sound levels and long service intervals, there is plenty of room for improvement. The APR Carbon Fiber Intake System increases performance primarily by improving mass airflow through the system while still proving adequate filtration. Expect greater horsepower and torque through the power band with a more direct and responsive feel upon pressing the throttle. Sounds from the engine and turbocharger are enhanced and some may even experience better fuel economy depending on driving style.

Research and Development

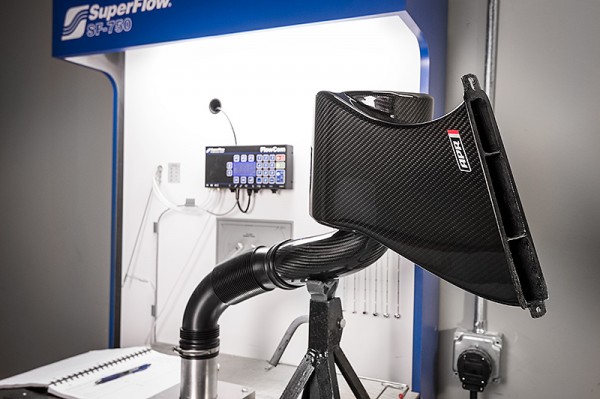

Uncommon to most in the market today, APR spared no expenses during the research and development period. For the better part of a year, APR’s Mechanical Engineers created several prototype intake designs utilizing our in house Sterolithography 3D printer and other rapid prototyping techniques. Various filter mediums were tested in conjunction with the new intake designs through simulated models, flow bench analysis, dyno data collection and in real world applications all in an effort to derive the best possible solution.

Engineering and Design Information

To increase performance over the factory intake system, the intake system’s ability to flow a higher mass of air is critical. In order to achieve this, APR’s Mechanical Engineers focused on improving the pressure ratio between the inlet and outlet of the intake system, reducing turbulence, maximizing filter efficiency and keeping IAT as low as possible.

Installation

The intake system comes pre-assembled from APR ready to be installed in minutes with minimal tools. With the factory unit removed, the intake slips into place and connects to the factory turbo inlet pipe using the OEM hardware without filling the engine bay with additional couplers and hose clamps. Because the system fits in the OEM location, it’s fully compatible with future upgrades from APR, including our larger Stage III Turbocharger Systems.

Improving the Pressure Ratio

In an effort to strive for an ideal pressure ratio (1:1) between the intake’s inlet and outlet, the intake features several key characteristics. Through CFD optimization and flow-bench validation, the intake’s filter housing was shaped into a reducing spiral, or volute, which uses the inertia of the air entering the system to increase pressure on the outside of the filter. This creates an even pressure distribution across the entire face of the filter, rather than only a few key spots, and as such, maximizes utilization of the filtration element. Compared to many other popular intake styles, the APR intake system allows for the use of a small, compact filter with better filter utilization as systems often twice its size. Unlike traditional open element filters, the APR intake design only pulls air from the leading edge of the vehicle’s hood. In doing so, it draws air from an area of relatively high pressure. As the vehicle increases in speed, pressure continues to build and ultimately aids in the intake’s effectiveness.

By sealing the intake system, pressure created during the ram air effect and volute design is not simply lost within the engine bay. This is contrary to open element filters that pull air from a relatively low pressure region formed within the engine bay.

Intake Air Temperature Management

Intake air temperature (IAT) plays a critical role in engine performance, especially on turbocharged engines where the ambient air temperature is raised twice through both compression via the turbocharger, and then again during the engine’s compression stroke.

In an effort to maintain the lowest possible starting IAT, the APR Intake system begins by drawing air from the coldest possible location, which is the front end of the vehicle before the radiator. Air travels a short path through the intake system, past the filter and on its way to the turbocharger through a sealed intake design that prevents ingestion of hot, under-hood. Finally, the intake’s carbon composite design features a thin fiberglass backing, which improves thermal insulative properties.

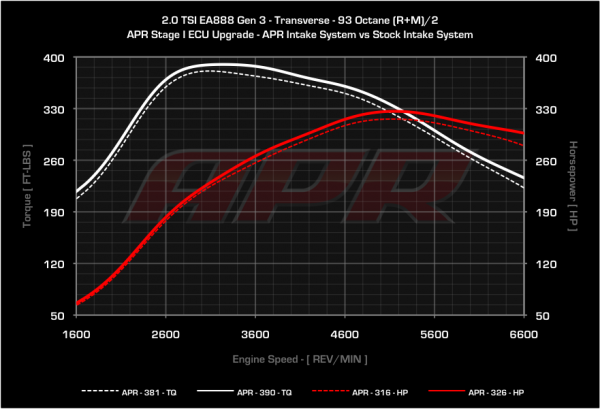

Dyno Results

Sound

In an effort to please customers unaware of the sounds caused by turbocharging an engine, as well as cross platform use on both economy and performance oriented vehicles, the OEM was tasked with creating an intake that many would consider to be too quiet for a performance vehicle. APR’s design requirements called for an intake system that only delivered the engine’s true turbocharged sound as air is sucked through the turbocharger or exhausted from the diverter valve upon lifting off the throttle. The inherent stiffness of carbon fiber composite material results in an induction resonance from the engine allowing the occupants to hear a clean and crisp intake note without being overbearing or cheap sounding in nature.

Please call 724-219-4167 or email sales@nltuning.com to place an order

| Make | Models | Engines | Part Number | Price | |

|---|---|---|---|---|---|

| Audi | A3 / S3 – (MK3 / Typ 8V) | 1.8 TFSI & 2.0 TFSI | CI100033 | $449.99 | Please Call to Order |

| Seat | Leon / Cupra – (MKIII / Typ 5F) | 1.8 TSI & 2.0 TSI | CI100033 | $449.99 | Please Call to Order |

| Skoda | Octavia / vRS – (MKIII / Typ 5E) | 1.8 TSI & 2.0 TSI | CI100033 | $449.99 | Please Call to Order |

| Volkswagen | Golf / GTI / R – (MK7 / A7 / Typ 5G) | 1.8 TSI & 2.0 TSI | CI100033 | $449.99 | Please Call to Order |